Bellingham began building its sewer system in 1892, installing heat-hardened clay pipes in developed areas of the city. These early sewers carried both sewage and rainwater, discharging the flow directly into Whatcom Creek and Bellingham Bay. In 1908, likely in response to sewer overloads, the city added its first storm sewers to those same developed areas.

Most of these early sewers are still in use. The city has since intercepted sewage flows and redirected them to the wastewater treatment plant, and we have removed stormwater connections from the sewer system.

The City began providing primary wastewater treatment in 1947, with a plant located near the mouth of Whatcom Creek. At that time, treated effluent was discharged into a shallow part of Bellingham Bay.

Post Point Resource Recovery Plant

In 1974, the City of Bellingham replaced the Whatcom Creek treatment plant with the Post Point Resource Recovery Plant at 200 McKenzie Avenue. The Post Point Resource Recovery Plant began providing primary treatment for up to a peak flow of 55 million gallons per day (mgd) for the areas served by sewer.

Today, wastewater flows into Post Point from more than 250 miles of sewer mains in Bellingham and surrounding communities. The plant also receives septic tank waste collected from private homes throughout Whatcom County.

In 1993, the City of Bellingham upgraded Post Point to include secondary treatment, investing $55 million in the improvements. This upgrade to secondary treatment increased contaminant removal to 95% before releasing the treated wastewater into Bellingham Bay.

The City’s Comprehensive Sewer Plan identified the need for additional wastewater treatment capacity at the Post Point Plant. A Facilities Planning process began in late 2009, aiming to complete the plan in 2011. Construction was completed in 2014.

The video below shows how we clean and treat wastewater at the Post Point Resource Recovery Plant.

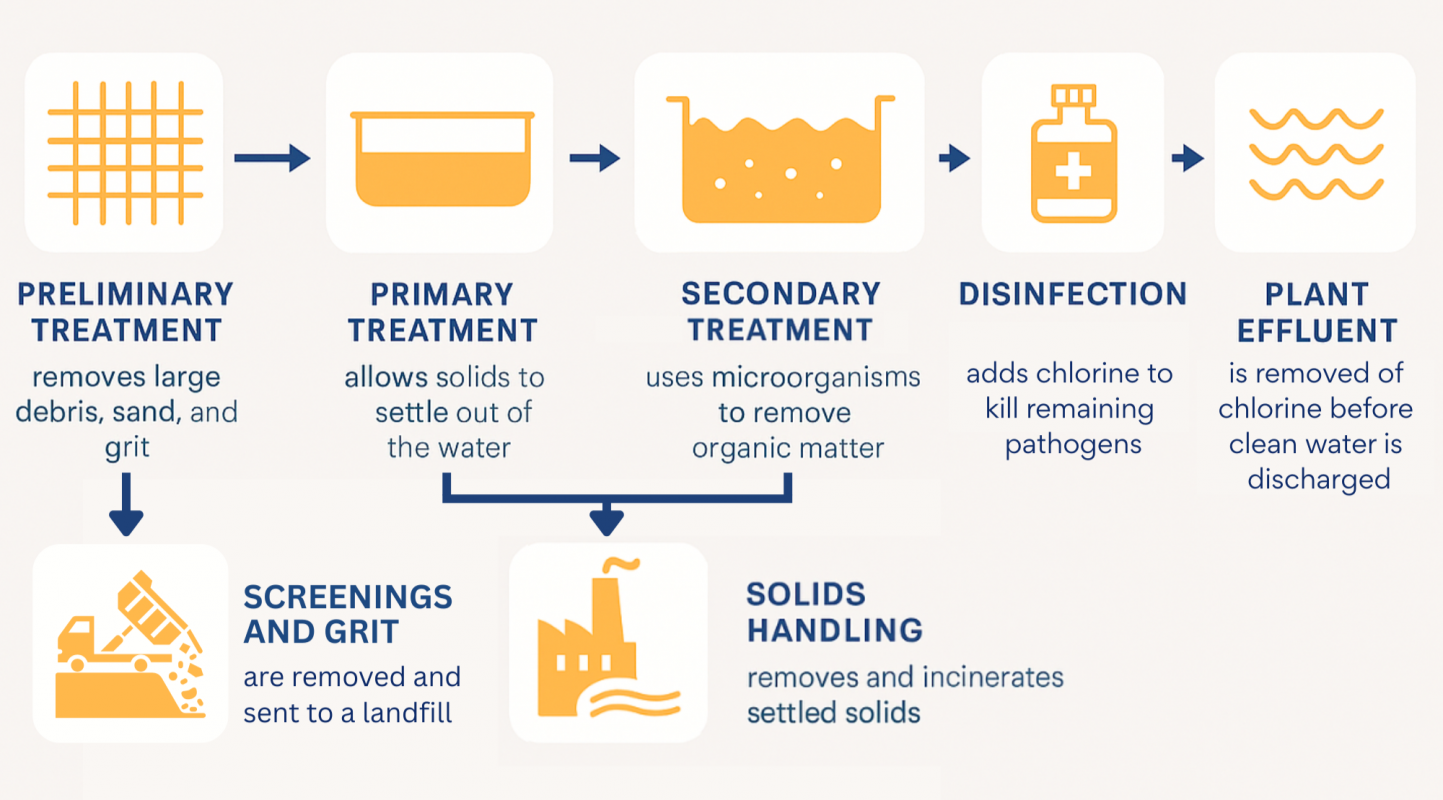

Wastewater Treatment Process

Preliminary Treatment

Preliminary treatment prepares wastewater for the rest of the treatment process by removing materials that could damage equipment or block flows. This stage also includes a receiving station for septic tank waste collected from across the county.

To control bacteria and reduce odors, the wastewater is first pre‑chlorinated and aerated. It then passes through coarse screens that remove rags and other large debris. Next, the flow enters detritor basins, where the water slows down, allowing sand and other heavy particles (called grit) to settle out.

The wastewater then moves on to primary treatment. Operators remove the collected screenings and grit from the system and send them to a landfill for disposal.

Primary Treatment

In the primary treatment stage, wastewater flows into large tanks called primary clarifiers, where it remains for about two hours.

During this time:

- Solids (called primary sludge) settle to the bottom.

- Oils and grease (called scum) rise to the surface and are skimmed off.

Operators pump both the sludge and scum from the clarifiers and send them to solids handling for incineration. The clarified wastewater then continues on to the next stage of treatment.

Secondary Treatment

Secondary treatment uses microorganisms, called activated sludge, to remove pollutants from the wastewater. This stage has two main steps:

Aeration Basins

Wastewater flows into large, enclosed aeration basins. Here, activated sludge is mixed with the wastewater, and air is added to create an ideal environment for microorganisms to trap and remove contaminants.

Secondary Clarifiers

From the aeration basins, the water moves into large secondary clarifiers. Here:

- Microorganisms settle to the bottom.

- Some are removed as waste activated sludge (secondary sludge).

- Others are returned to the aeration basins as return activated sludge to repeat the process.

At this point, the water is about 95% pure. The treated wastewater then flows to the disinfection stage, while the secondary sludge is pumped to solids handling for incineration.

Disinfection

After secondary treatment, wastewater spends about one hour in the chlorine contact chamber. Chlorine is added to kill any remaining disease‑causing organisms. To protect fish and other aquatic life, sodium bisulfite is then added to neutralize the chlorine before the water is released.

Microscopic protozoa also play a role in treating the water before it is discharged into Bellingham Bay. Throughout the process, laboratory staff regularly collect samples and run tests to make sure the treatment plant is operating efficiently and that the water released is safe for the environment.

Plant Effluent

After treatment, the water is discharged into Bellingham Bay through an outfall located a quarter mile offshore at a depth of 60 feet.

The Post Point Wastewater Treatment Plant achieves about 95% removal of organics and solids in the treated effluent. On average, the discharged water has:

- Total suspended solids (TSS): 7 ppm

- Biochemical oxygen demand (BOD): 9 parts per million (ppm)

Solids Handling

Sludge from the treatment process is managed in several steps:

- Thickening – Primary and secondary sludge are mixed with a polymer and placed on a gravity belt to thicken the material.

- Dewatering – High‑speed centrifuges remove excess water from the thickened sludge.

- Incineration – The dewatered sludge is burned in two multiple‑hearth, gas‑fired incinerators at about 1,500°F. This reduces the volume by roughly 90% and destroys all pathogens.

- Air Quality Protection – Exhaust gases pass through an afterburner, two wet scrubbers, and an electrostatic precipitator to protect air quality.

Learn more about how we manage our wastewater solids, including upgrades to air emission controls and evaluation of alternatives on our Wastewater Solids Management page.

Laboratory

The City of Bellingham operates a state‑certified laboratory at the treatment plant.

The lab performs two key functions:

- Compliance testing to meet the requirements of the plant’s National Pollutant Discharge Elimination System (NPDES) permit.

- Process control testing is conducted at each stage of treatment to ensure the plant operates efficiently.

Administration/Control

State-certified plant operators are on duty 24 hours a day to monitor and control the treatment process. The plant is fully automated and has a state-of-the-art computer system that provides operators with accurate and up-to-date information.

Educational Information

Visit the Environmental Education Site for Videos, Written Curriculum, and Tours.