Constructed in 1968 and upgraded in 2018, the City of Bellingham’s Water Treatment Plant (WTP) can process up to 24 million gallons of water a day (MGD). Over the years, the plant has been updated to include the latest in water treatment technology including computer controls and specialized water quality testing instruments. The WTP uses what is known as an in-line or contact filtration process. This process includes adding a special chemical to the water that clumps unwanted particles before the water is filtered. This type of treatment is preferred for high-quality water like we have in Bellingham.

Lake Whatcom serves as the drinking water source for Bellingham and outlying areas with additional water coming from the Middle Fork of the Nooksack River via the Deming Glacier on Mt. Baker. Lake water enters an underwater pipe and travels to the WTP by gravity where it first enters an area known as the gatehouse. This is where the water passes from the pipe to a tunnel that connects to the next area called the screenhouse in Whatcom Falls park. In the screenhouse, larger sized debris are removed by a screen.

After going through the screen, the water travels through another pipe to the WTP located near the park. Once it reaches the WTP, it enters the pretreatment system called Dissolved Air Floatation (DAF). A chemical called aluminum sulfate (alum) is mixed in the water to help remove smaller sized particles and algae.

In the DAF pretreatment system, very small bubbles are used to float the clumped particles to the surface of the water where they are skimmed off and sent to the Wastewater Treatment Plant.

After DAF, a small amount of chlorine is added to the water. This helps with the filtration process and prevents algae from growing in the pipes that are in contact with the unfiltered water. The water flows from the DAF into a flume where a filter material called polymer is added to clump even more smaller particles together, such as dirt, algae, and sediment. The water then flows into one of six filters, which contain layers of material called anthracite coal, and silica sand. The water flows through the two layers of material, trapping any remaining particles. The filtered water is then collected at the bottom of the filter using what is called an underdrain system.

After filtration through the filters, the water flows from the underdrain system into a 1-million-gallon reservoir located beneath the plant called the clearwell. Chlorine is added to the clearwell to ensure there is proper chlorine levels before entering the Contact Time (CT) Reservoir. This is a 16-million-gallon reservoir where the water sits while the chlorine blends with the water. The water then flows out of the CT reservoir where a final dose of more chlorine is added to ensure there is enough. Sodium carbonate (soda ash) is also added at this point to raise the pH of the treated water so it does not ruin the 410 miles of water mains and our water customer’s plumbing.

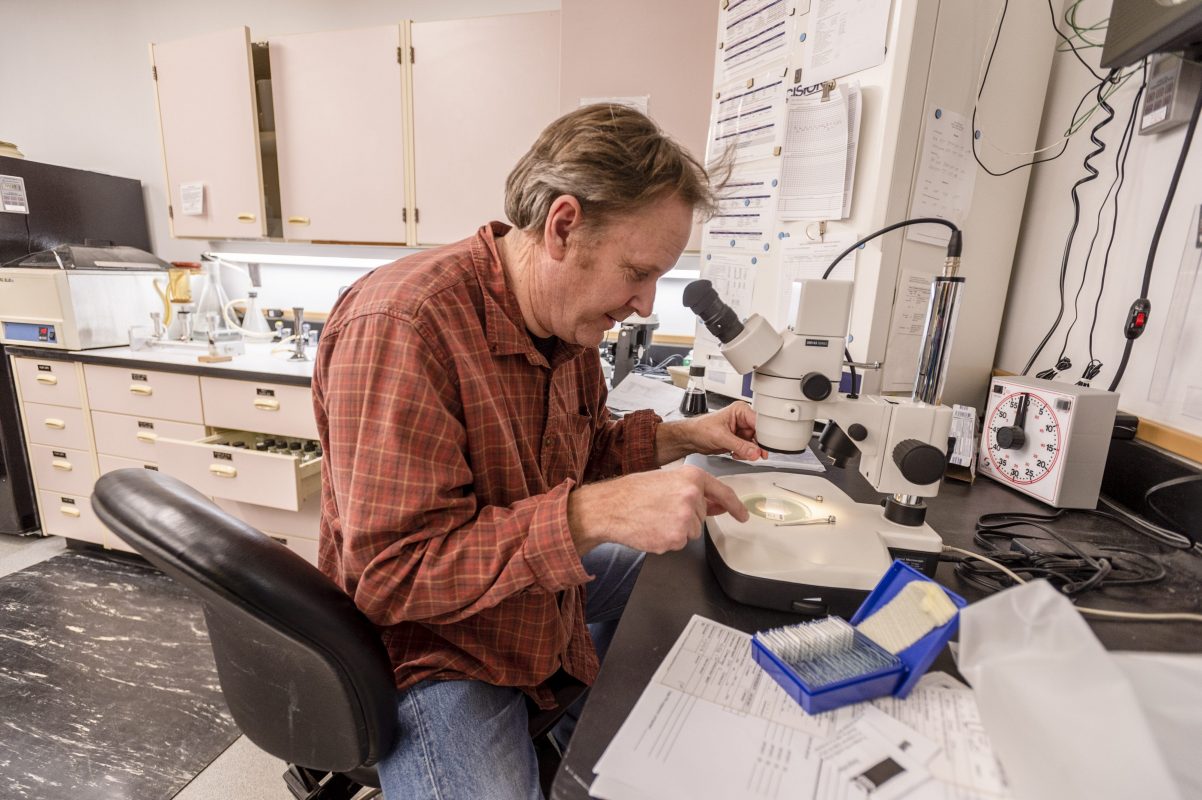

Water quality testing is performed throughout the day at various locations in the water treatment plant with online monitors, verifying its safety 24 hours a day. The City of Bellingham also operates a state-certified laboratory at the WTP. Extensive water quality monitoring is also done throughout the distribution system each day. Treated water quality is monitored to meet the requirements of the Safe Drinking Water Act and the requirements of the Washington State Department of Health. Results are regularly analyzed for more than one hundred sixty (160) constituents.

After leaving the WTP, over ninety designated stations located throughout the City’s water distribution system are sampled each month to verify the safety of the treated drinking water. These stations are in different places and help to assess the water quality as it travels through the drinking water distribution system.

For more information about treated water quality and monitoring programs visit Water Treatment Steps or contact the Technical Supervisor at the Operations Division of the Public Works Department.

Public Education

Over the last several years, the City of Bellingham has developed and implemented an extensive and highly successful public education program focusing on the City’s water supply. The program serves schools, civic groups, drinking water customers, watershed residents and other community interests, with the goal of increasing public awareness of water resources, water quality, and water conservation issues.